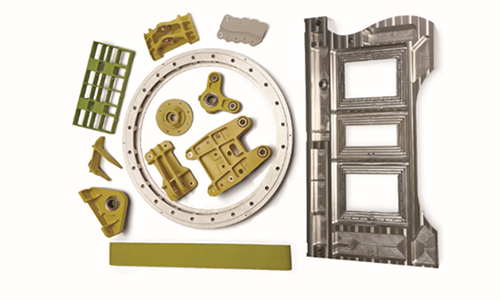

At Zentark, we offer cutting-edge CNC and VMC machining solutions to meet the precision manufacturing needs of our clients across various industries. Our state-of-the-art machinery and experienced team enable us to deliver high-quality components with exceptional accuracy and efficiency.

CNC Turning Machines:

CNC machining is a manufacturing process that utilizes computerized controls and machine tools to remove material from a workpiece to create a custom-designed part or product. At Zentark, we specialize in CNC machining, leveraging advanced technology and precise programming to produce complex components with tight tolerances.

Key Features of Our CNC Machining Services:

- Precision and Accuracy: Our CNC machines are equipped with cutting-edge technology and high-precision tools, allowing us to achieve tight tolerances and ensure consistent quality across all components.

- Versatility: With CNC machining, we have the flexibility to work with a wide range of materials, including metals, plastics, and composites, to meet the diverse needs of our clients.

- Efficiency: CNC machining offers unparalleled efficiency and productivity, with automated processes that reduce lead times and minimize errors, resulting in faster turnaround times for our clients.

- Customization: We offer custom CNC machining services tailored to the specific requirements of each project, from prototype development to large-scale production runs.

VMC Machining:

Vertical Machining Centers (VMCs) are a type of CNC machine tool that operates with a vertically oriented spindle, making them ideal for machining operations that require precision drilling, milling, and tapping. At Zentark, our VMC machining capabilities enable us to produce complex components with superior surface finishes and dimensional accuracy.

Key Features of Our VMC Machining Services:

- High-Speed Machining: Our VMC machines are equipped with high-speed spindles and advanced tooling systems, allowing us to achieve rapid